The aerospace sector relies on laser blasting to remove mastic from parts; clean turbine blades; remove labels from fuselage; and clean hydraulics,

Laser blasting is ideal for cleaning engine blocks and components, undercarriages, wheels and axles, automotive production equipment, and mor

Laser blasting is frequently used to remove charring, ash, and other damage from otherwise usable building components after a fire.

Plastic molders use this method to remove residue and waste material from conveyor systems, mold and extruder equipment; resin removal; polyurethane removal; and deburring plastic parts.

Laser blasting helps printers keep equipment clean, such as drums, grippers, rollers, side walls, ink trays, gears, print decks, guide escalators, delivery units, feeders, conveyors, gluers, and paper converting equipment.

Laser blasting offers a reliable means for removing contaminants from production surfaces of all types

Bakeries and food production operations often use laser blasting to clean food waste and oils from ovens, bins, conveyors, belts, mixers, tubes, fans, seals, and production facility walls

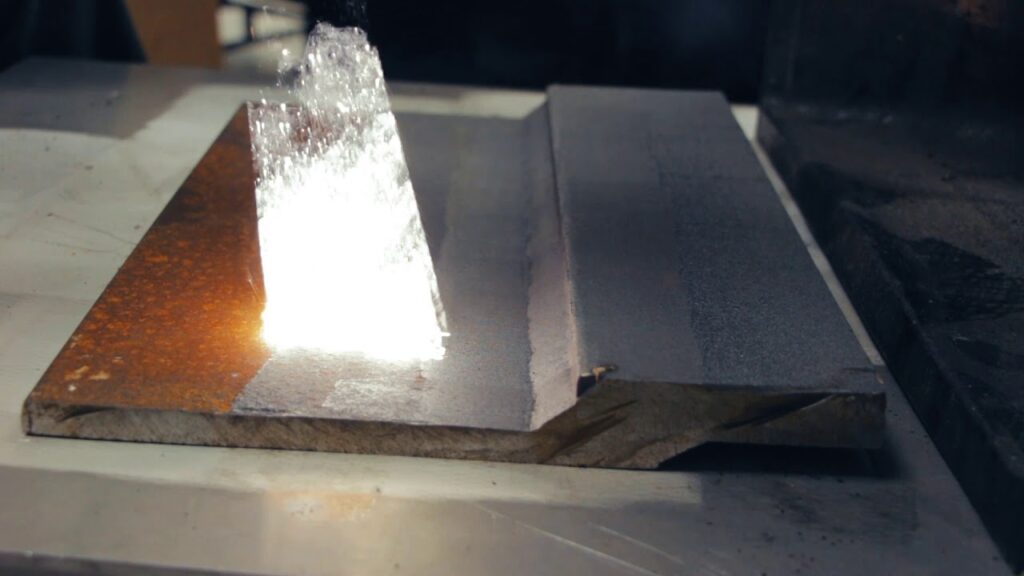

Foundries use this process for cleaning molds and press equipment, stripping rust and paint, deburring, cleaning welding robots, residue removal, and more.

Unlike laser blasting, abrasive blasting is highly toxic and dangerous for the operator.

This is a variation of abrasive blasting with the same positive toxic, environmental and conductive qualities

Like dry ice blasting, pressure washing is non-abrasive and not harmful to the environment due to emissions or toxic.

Cleaning with chemicals & solvents is another common non-abrasive cleaning method with no electrical issues.